Introduction

This white paper provides an overview of Electric Field Vector Mapping (EFVM) and Electronic Leak Detection (ELD) testing, as presented by Tyrone Buwee on September 27, 2024. The presentation is part of a continuing education program registered with the American Institute of Architects (AIA).

Learning Objectives

The presentation aims to:

- Provide a basic understanding of EFVM and ELD testing.

- Explain how to perform EFVM and ELD testing.

- Demonstrate the ability to document the results of EFVM and ELD testing.

- Discuss the advantages and disadvantages of EFVM and ELD testing.

Understanding EFVM and ELD

EFVM and ELD are non-destructive testing methods used to locate breaches or voids in waterproofing membranes. EFVM uses an electrical field to detect leaks, while ELD can use either high or low voltage to achieve the same goal.

Definitions and Terms

- EFVM: Specifically refers to low voltage leak detection using an electronic field.

- ELD: Covers both high and low voltage leak detection methods.

History of ELD

- High Voltage ELD: The original method, using a positive charge to locate breaches.

- Low Voltage ELD: Introduced in the mid-1990s in Germany and later in North America in the late 1990s.

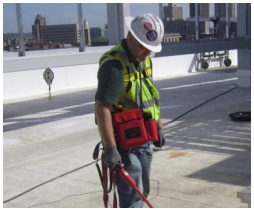

EFVM Testing Process

- Setup: A grid wire is laid out, and water is applied to the membrane surface to act as a conductive medium.

- Testing: The EFVM equipment delivers a low voltage pulsating electrical charge between the non-conductive waterproofing membrane and the conductive structural deck.

- Inspection: Technicians visually inspect wall junctions, perimeter details, and membrane penetrations.

- Detection: Breaches in the membrane cause an electrical connection, detected by the equipment to pinpoint the leak.

Reporting

- Breaches must be clearly identified in the field.

- Documentation is crucial for both quality control and future reference.

Advantages

- Effective for both existing and new constructions.

- Can replace flood tests.

- Detects pinholes invisible to the naked eye.

Disadvantages

- Conductive primers/adhesives are necessary for a good ground.

- High carbon content in membranes can hinder ELD testing.

Conclusion

- ELD (High Voltage): Faster but requires a dry surface.

- EFVM (Low Voltage): Slower and requires a wet surface.