Our Services

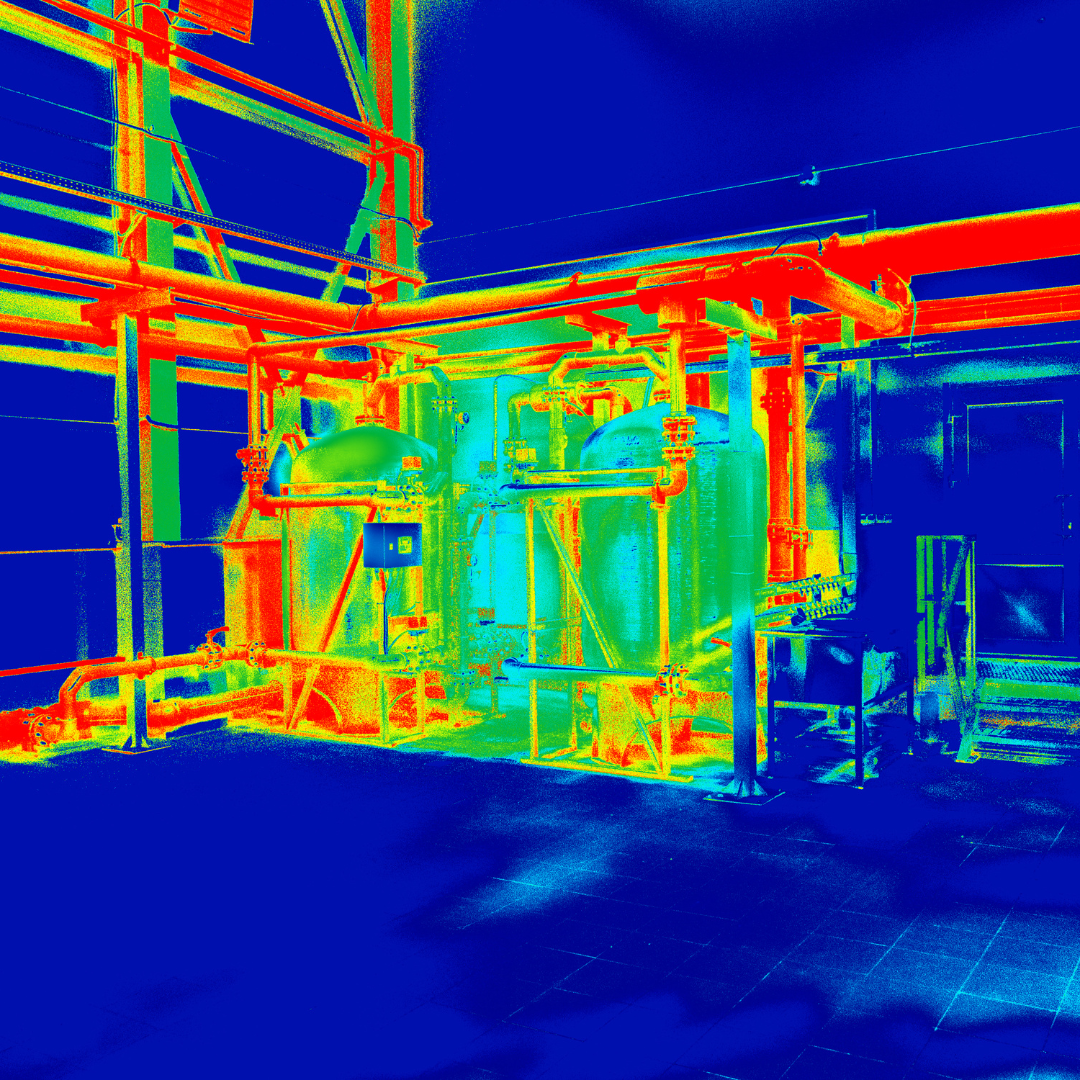

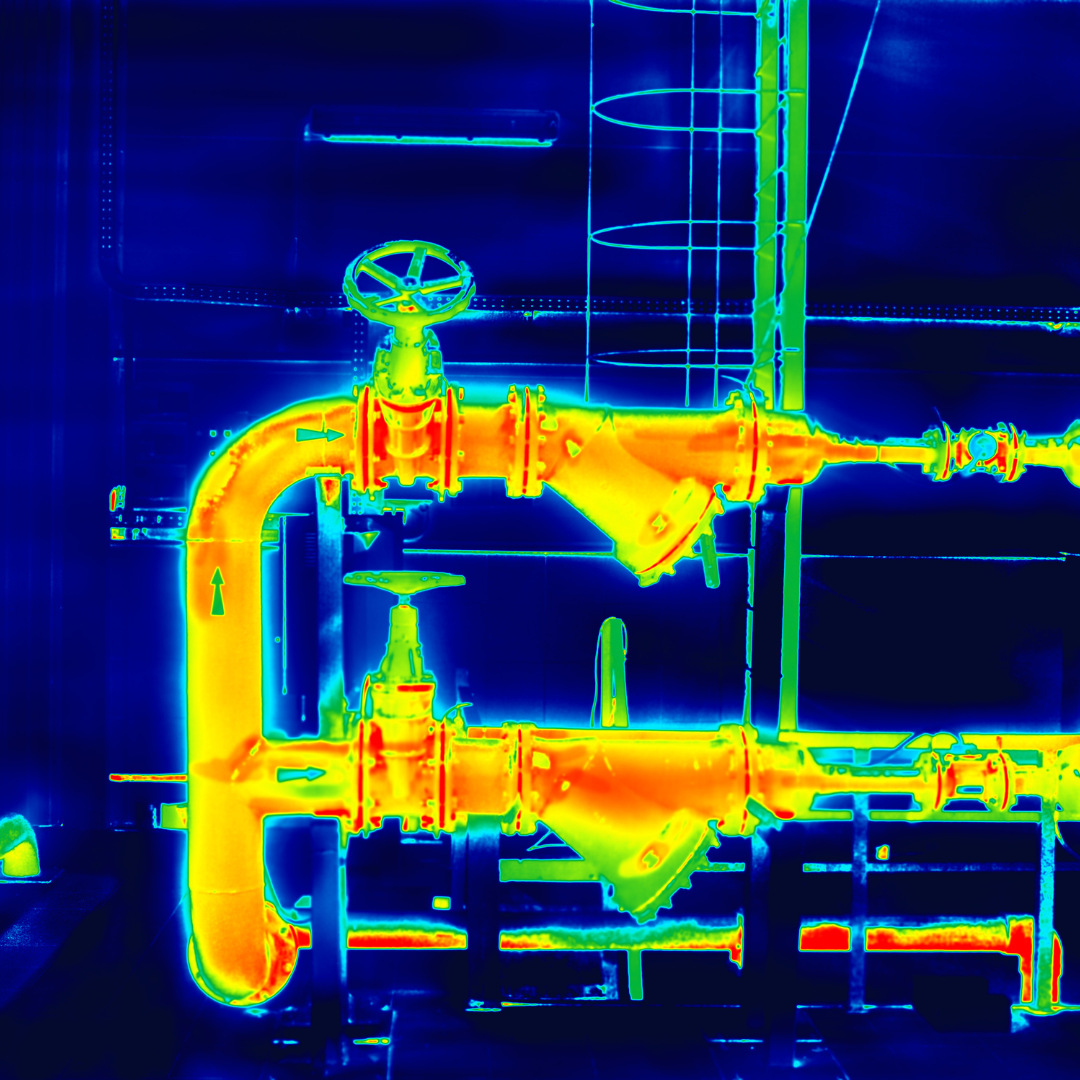

Infrared Thermography Inspection

Infrared thermography inspection, a non-destructive testing technique, has emerged as a powerful tool across various industries for detecting, analyzing, and preventing potential issues.

Boosting Maintenance Efficiency

Infrared thermography uses infrared radiation to visualize temperature variations in objects, identifying potential issues across various applications like electrical systems and building inspections. This technology enhances safety, efficiency, and cost-effectiveness. Within Planned Maintenance Programs, it captures thermal images of electrical components to detect overheating issues caused by loose connections, overloaded circuits, or faulty equipment. Early detection allows for proactive maintenance, preventing costly downtime, equipment failures, and safety hazards.

Precision Maintenance Insights

Infrared thermography has transformed building inspections by enabling precise assessments of structural integrity, energy efficiency, and moisture intrusion. It identifies areas of heat loss, air leakage, and insulation flaws, facilitating energy savings and comfort enhancements. Additionally, it detects moisture infiltration, helping prevent mold, structural damage, and indoor air quality problems. In mechanical systems, thermography is crucial for monitoring equipment conditions, identifying issues like friction, misalignments, and bearing failures in machinery, thus preventing breakdowns, optimizing performance, and extending asset lifespans.

Safety & Compliance for Industrial Settings

Successful infrared thermography requires specialized training and equipment, as certified thermographers need to accurately interpret thermal images to make informed decisions. Used for process monitoring, quality control, and safety assurance, infrared inspection detects abnormalities in industrial settings like chemical reactors and pipelines, identifying leaks and insulation failures. Regular thermographic inspections help maintain regulatory compliance, minimize environmental impact, and ensure safety in industrial facilities.